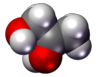

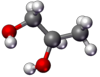

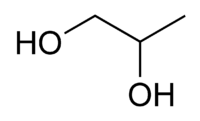

MPG - USP (HO-Ch2 - CH2 - (OH) - CH3)

MPG – Industrial is a high purity grade of monopropylene glycol (MPG). It is a clear, colourless and practically odourless, hygroscopic liquid, completely soluble in water. MPG – Industrial is miscible in all proportions with low molecular weight aliphatic alcohols and ketones. It is slightly to moderately soluble in aromatics hydrocarbon solvents and only slightly miscible with aliphatics hydrocarbon solvents.

Applications

Monopropylene glycol finds its major application as a building block in unsaturated polyester resins. Other major applications are as a component in heat transfer fluids, de-icers for aircraft, grinding aids in cement industry and intermediates for chemical products like glycol based ethers, surfactants and plasticisers.

Storage and Handling

MPG – Industrial is slightly hygroscopic and must be stored under conditions so that contamination with water and absorption of moisture are prevented.

The storage temperature of MPG – Industrial is not critical, in that there will be no hazardous conditions created by the storage of the product at any ambient temperature likely to be encountered. It should be noted however that for product quality reasons the storage temperature should not exceed 40 ºC. At below freezing temperatures the product viscosity might become too high for transfer from the storage container with the pumps available.MPG – Industrial is stable product and is not expected to deteriorate significantly with time providing it is stored as indicated.

|

|

Safety Phrases: 24/25 |

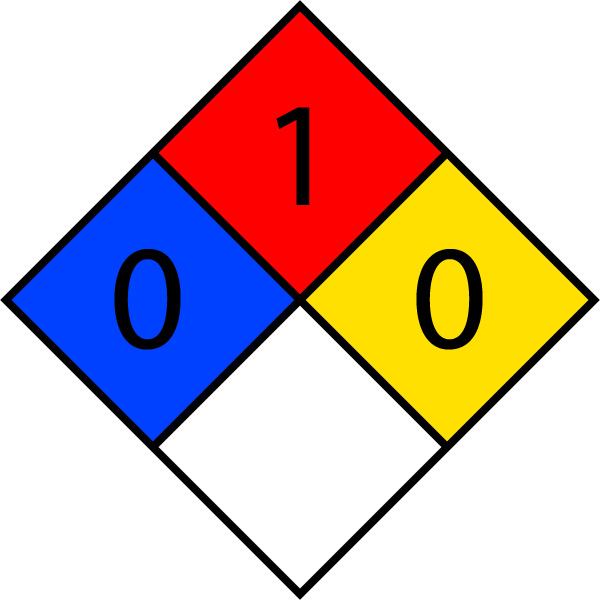

| Chemical Structure | NFPA 704 |