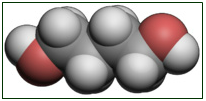

BUTANDIOL

Chemical Formula : C4H10O2 CAS Registry Number 110-63-4

1,4-Butanediol is the organic compound with the formula HOCH2CH2CH2CH2OH. This colorless viscous liquid is derived from butane by placement of alcohol groups at each end of the chain. It is one of four stable isomers of butanediol.

1,4-Butanediol is used industrially as a solvent and in the manufacture of some types of plastics, elastic fibers and polyurethanes. In organic chemistry, 1,4-butanediol is used for the synthesis of γ-butyrolactone (GBL). In the presence of phosphoric acid and high temperature, it dehydrates to the important solvent tetrahydrofuran. At about 200 °C in the presence of soluble ruthenium catalysts, the diol undergoes dehydrogenation to form butyrolactone.

|

Chemical Properties Appearance: Colorless viscous liquid.

Odor: Odorless.

Solubility: Complete (100%)

Specific Gravity: 1.0171 @ 20°C/4°C

pH: No information found.

% Volatiles by volume @ 21°C (70°F): N/A

Boiling Point: 230°C (446°F)

Melting Point: 20.1°C (68°F)

Vapor Density (Air=1): 3.1

Vapor Pressure (mm Hg): 0.01 @ 25°C (77°F)

Evaporation Rate (BuAc=1): Nonvolatile.

|

|

Applications

Polyurethanes Polyurethanes offer more opportunities for attaching monomers than other plastics and are, thus, suitable for numerous applications. The most important fields of application are soft and rigid foams, microcellular elastomers (soft integral skin foams), laminates, surface coatings, adhesives, thermoplastics, fibers and dispersions. Polybutyleneterephthalate Polybutyleneterephthalate (PBT) is a thermoplastic polyester produced by the polycondensation of 1,4-butanediol with terephthalic acid or dimethylterephthalate. Preference is usually given to the reaction with the ester, which can be purified more easily to the degree required for polycondensation.Some of the most important fields of applications for PBT are engineering materials, where PBT is able to compete with many engineering-grade thermoplastics and thermosetting plastics. PBT possesses superior outdoor performance, low water absorption, good dielectric properties, dimensional stability, satisfactory impact strength and the retention of these beneficial properties on exposure to fluctuating humidity or to chemicals. PBT is also used in hot-melt adhesives because of its high temperature stability, rapid crystallization, favorable flow at the processing temperature and good flexibility. |

|

Hazards

NFPA Rating |

Risk Phrases: 22

Safety Phrases: 24/25

|